Multiscale Mask-less Laser Lithography

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Prototyping

- Masters (origination)

- Service

-

Market

- AR/VR/MR

- Automotive

- Lighting

- Optical instrumentation

- Security & Branding

-

Manufacturing Pillar

- Roll-2-Roll

-

Technology

- Laser Lithography - Maskless

Organisation

Offering Description

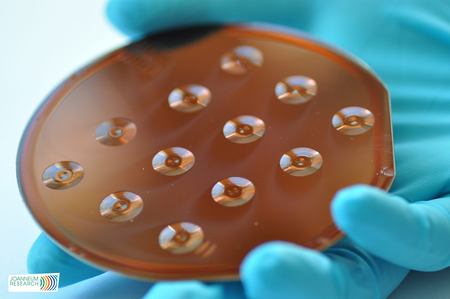

Origination by mask-less Laser Lithography

Our unique mask-less laser lithography enables the low-cost production of novel and complex high-resolution sub-micro and micro-structures:

- Master fabrication e.g. for UV-nanoimprint lithography, hot-embossing, high precision optical injection moulding, vacuum resin casting

- a Rapid prototyping in Micro-Optics, Photonics, Microfluidics, Electronics and others

Several advantages can be realised:

- Reduction of process time

- digital, non-photomask-based production

- quick and flexible to test and implement design changes

- fabrication of microstructures on flat and curved substrates via 5-axes nano-positioning system

Applications can be found in

- Free form micro optics for innovative illumination designs

- Diffractive and refractive micro optical elements

- Bionic surfaces in aviation for reduction of drag to reduce fuel consumption

- Microfluidic Lab-on-Chip systems for molecular diagnostics

- Micro-Electronics

Offering Specifications

- High quality fabrication of sub-micro and micro-structures on large area formats (2″, 4″, possibly 6″ substrate)

- Structures can have a 1D, 2D, or stepless (2.5 D) relief shape

- Minimum structure size achieved in the lateral direction of our system is in the range of 300 nm

- Maximum structure depth for 2.5D microstructures is in the range of 80 μm

- Aspect ratio of 4 is possible

- Depending on the complexity of the designed microstructure, the processing time is approx. 1 hour per cm2