Light Guiding Elements

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Production

- Volume production

- Pilot production

-

Market

- Automotive

- Decoration & Luxury

- Imagers & Displays

- Lighting

- Solar, Energy & Daylight

-

Manufacturing Pillar

- Other

-

Technology

- 3D printing

Organisation

Offering Description

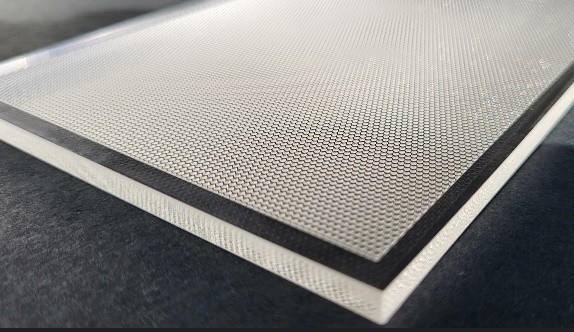

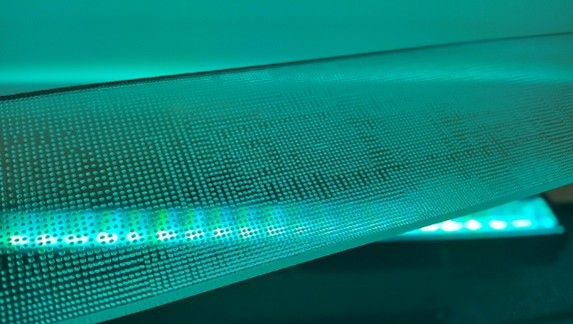

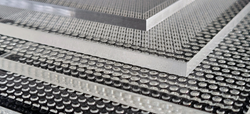

Modern day light guides are used for the transportation of light signals from a PCB mounted LED via a particular route to a defined light-emitting surface, with minimal light loss and blurring effects. Light Guiding Elements are generated to customer specifications using advanced Luximprint Design Software. Patterns can be generated in a linear, diagonal or freeform manner and may have identical or progressively increasing or declining pitches. Light Guiding Elements can be cut to specific geometric or freeform shapes and intend to transform side lit plates into uniform or selectively back lit luminous surfaces.

Offering Specifications

- High accuracy feature placement for uniform or targeted light distribution

- Large Format Optics: from small to 1200*650 mm sizes and beyond

- Flexible or rigid optically clear base materials

- Optional frosted, matte, or glossy surface finishes

- No additional tooling or post-processing required

- Decorative Optographix effects integrated natively