2D Fiber Alignment Arrays

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Volume production

- Pilot production

- Prototyping

-

Market

- Optical communication

-

Manufacturing Pillar

- Wafer-scale

-

Technology

- Cutting, Drilling, Dicing

- Laser Micromachining

- Wet Etching

Organisation

Offering Description

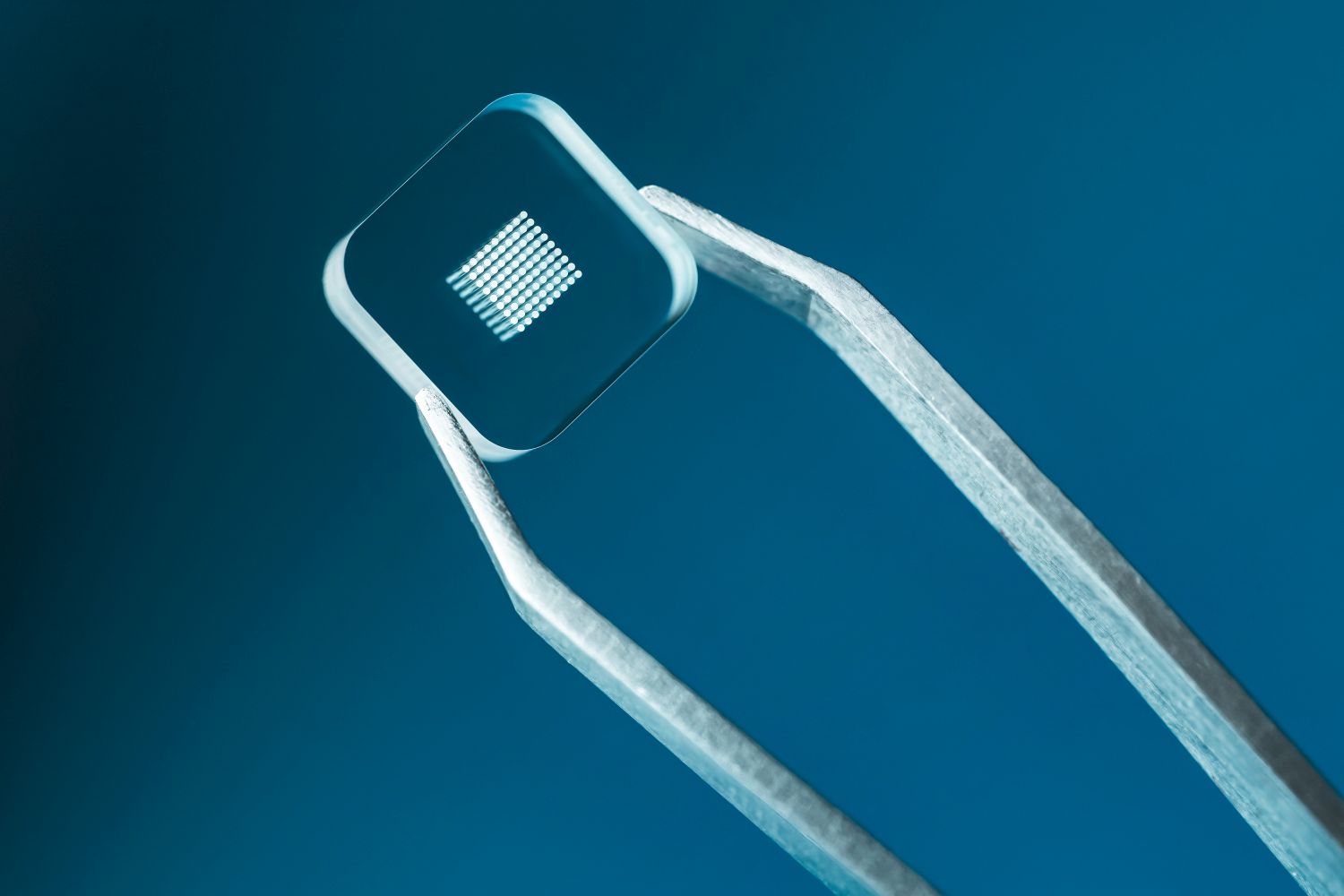

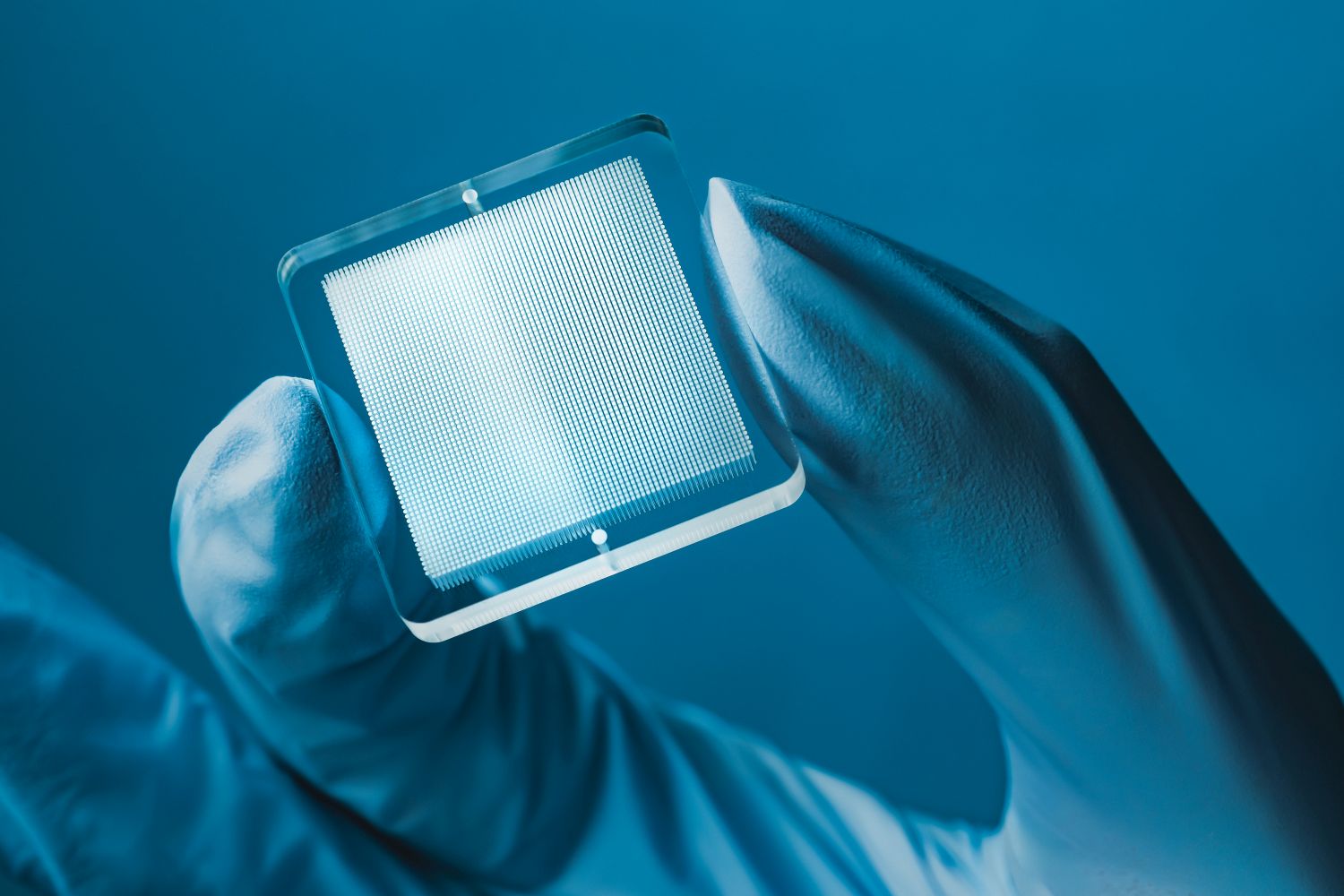

While there are one-dimensional (1D) and two-dimensional (2D) arrays, the need for speed and the growing volume of data drive demand for 2D fiber arrays.

The main reasons are:

- 2D fiber arrays hold fibers in a matrix arrangement (rows × columns), unlike conventional 1D fiber arrays (fibers in a single row, e.g., 12 or 16 channels).

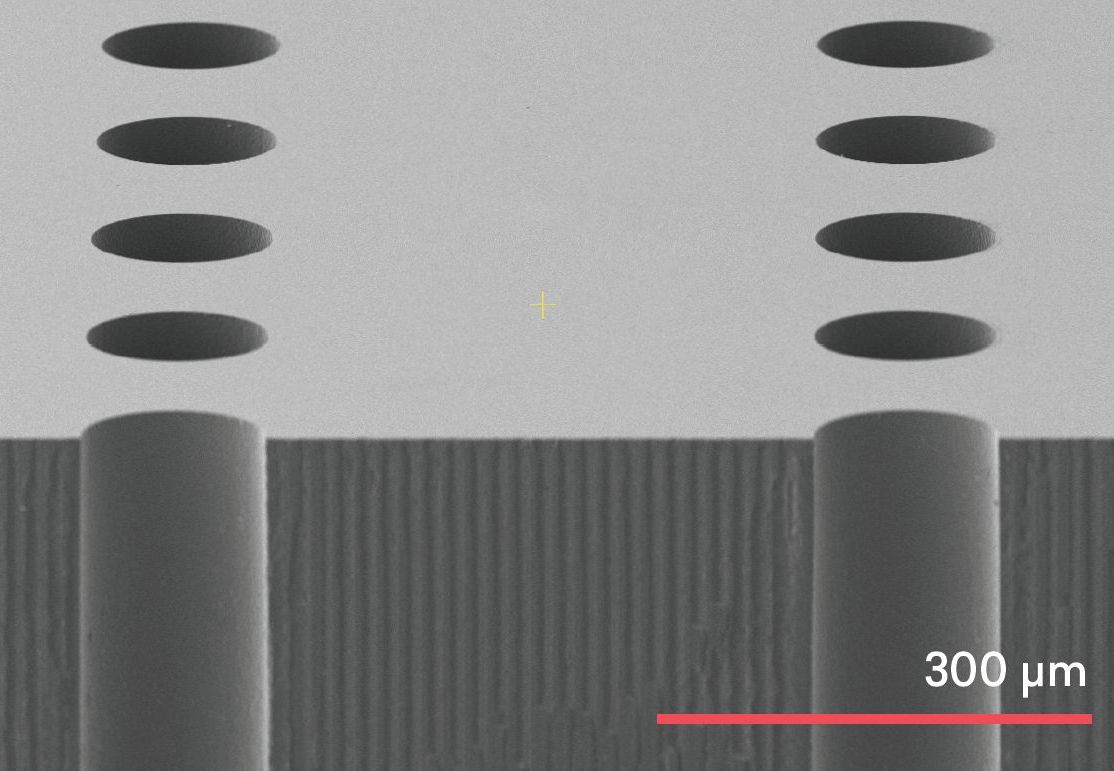

- Allows hundreds of fibers to be packed in a dense footprint, as they are precision glass plates with micron-scale holes or grooves, drilled and etched in 2D.

- Made from fused silica or high-purity borosilicate glass, due to its low CTE and dimensional stability.

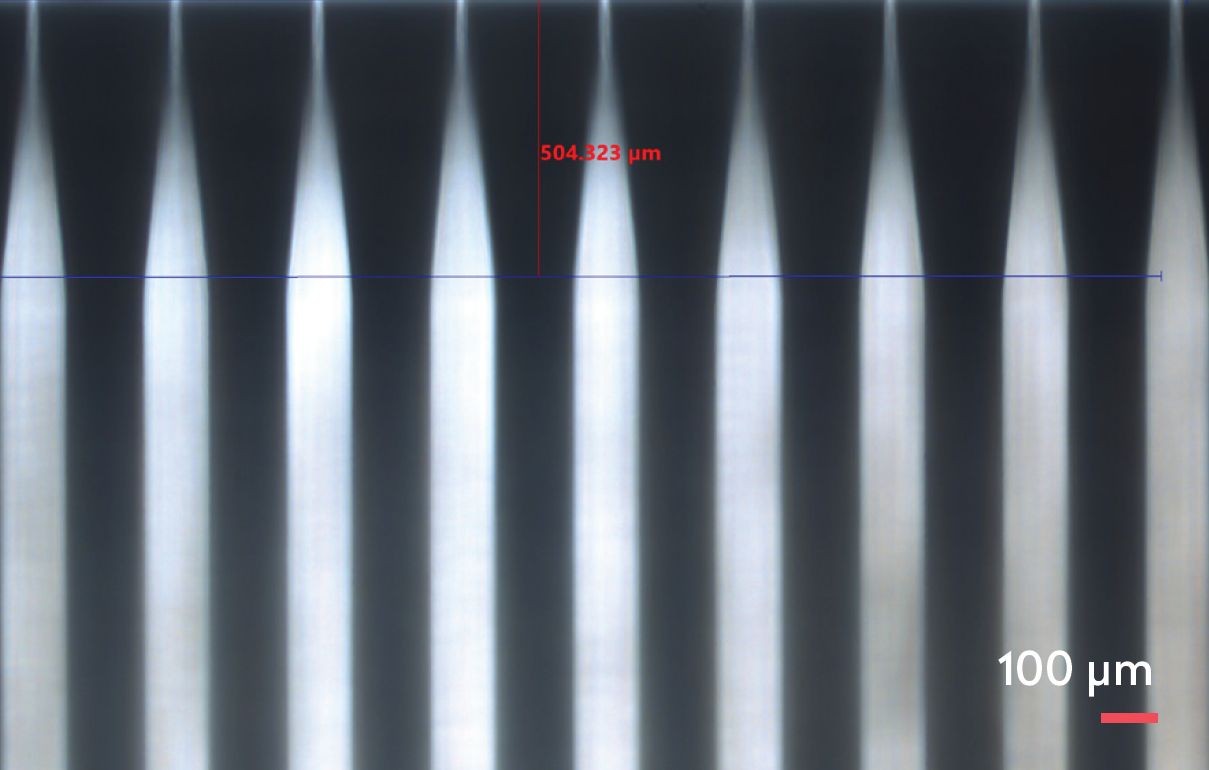

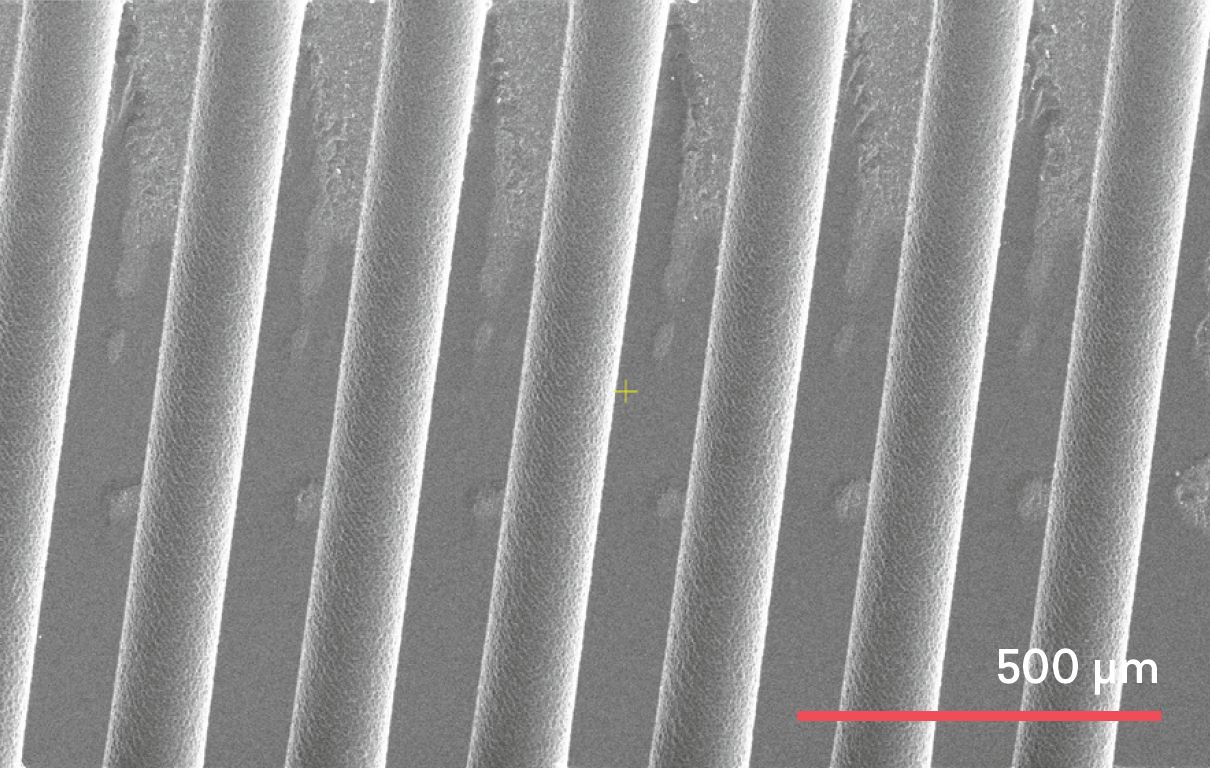

The production process of 2D optical fiber arrays is more complex than that of 1D arrays. While 2D arrays can be fabricated using diverse techniques, WOP utilizes femtosecond

laser micromachining, followed by selective laser-induced etching (SLE), which demonstrates definite advantages in precision, consistency, speed, material versatility, and cost-effectiveness.

Using our laser micromachining method for fiber arrays fabrication, critical features such as tight tolerances, tight positional accuracies, and hole diameter – within the tolerance of ±0.5 μm – can be achieved. This tight control of metrics ensures well-controlled alignment that might reduce insertion loss and provide good repeatability.

Moreover, this method enables forming the hole entrance as a funnel, step profile, or with a conical taper for easy fiber insertion. The channels can be straight or angled (like 8̊ ).

Offering Specifications

- Ultra-high precision

- Tight tolerances within ±0.5 µm

- Straight, flared, or with a cone for easier insertion

- Designed for standard SMF fibers, diameter 125/250 µm, also reduced clad fiber 80 µm (not limited)

- High density, standard 0,25 mm pitch

- Straight or angled holes