Laser Dicing of glass based wafer level manufactured products

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Service

-

Market

- AR/VR/MR

- Automotive

- Consumer Products

- Decoration & Luxury

- Healthcare & Life Sciences

- Imagers & Displays

- Lighting

-

Manufacturing Pillar

- Wafer-scale

-

Technology

- Cutting, Drilling, Dicing

Organisation

Offering Description

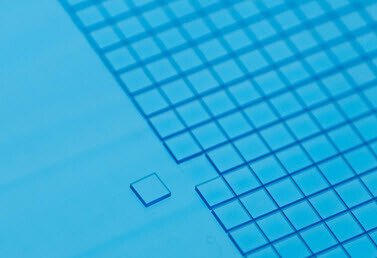

Laser-based dicing of glass wafers for up to 300 mm diameter provides a high quality as well as a high throughput solution for dicing of glass-based products. This technology can be applied to glass wafers for Microfluidic, ME(O)MS and other semiconductor applications as for sensor cover glasses.

Based on a die per wafer calculation and nominal processing speeds for laser and breaking technologies, a wafer per hour performance for small dies can be calculated. e.g. for a 3 mm square die design on a 300 mm diameter wafers, a dicing takt of ~10 wafers per hours can be expected.

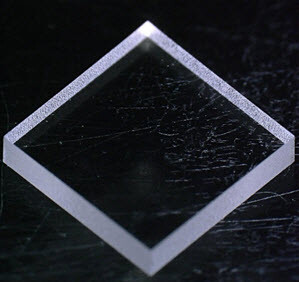

Exemplary investigations of a Corning® HPFS® Fused Silica (HPFS) glass wafer demonstrate the exceptional performance for chipping and edge quality and provide a quality, where the chipping performance is better than 50 µm with very precise edges and die corners.

Offering Specifications

We provide the laser dicing process solutions from small scale prototyping investigations to pilot production at our site to tool sales for a full manufacturing solution.