Lens Arrays and Lens Array Masters

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Masters (origination)

-

Market

- AR/VR/MR

- Automotive

- Consumer Products

- Decoration & Luxury

- Healthcare & Life Sciences

- Imagers & Displays

- Lighting

- Optical instrumentation

- Transportation

-

Manufacturing Pillar

- Wafer-scale

- Roll-2-Plate

- Roll-2-Roll

- Other

-

Technology

- Diamond Micro Machining

Organisation

Offering Description

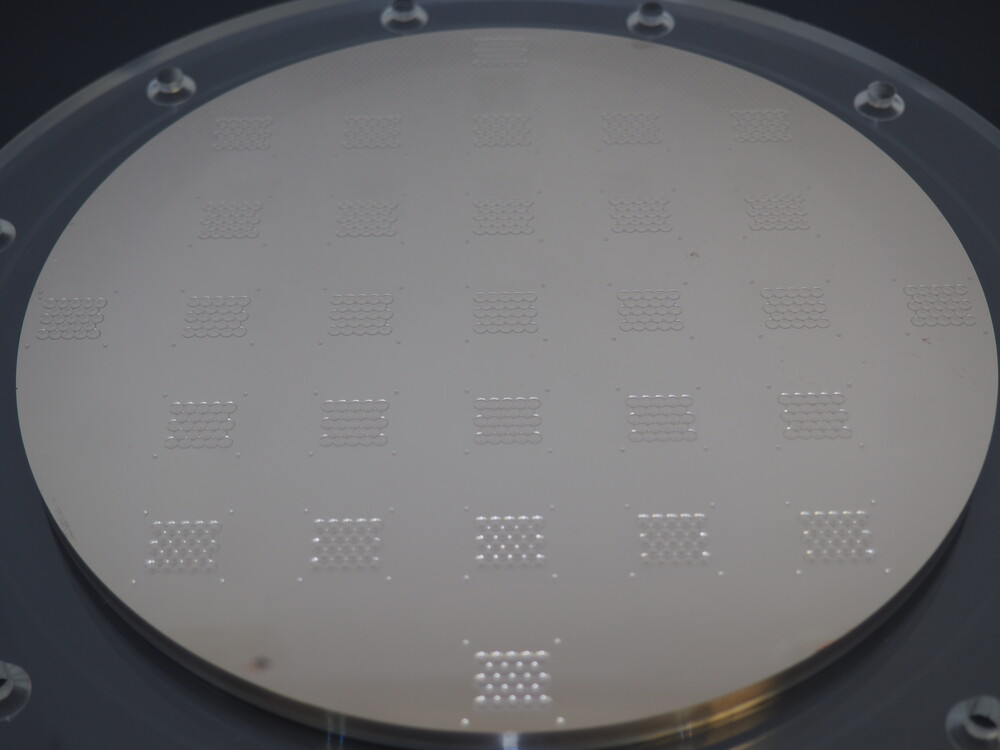

Wielandts UPMT has developed a unique patented technology called DPI® ( Dynamic Part Indexing ) that is a real breakthrough solution for the machining of lens arrays and monolithic multi-cavity molds by diamond machining. Using this technology, Wielandts UPMT manufactures lens array masters to customer specifications for diverse applications: MLA masters for automotive lighting, fully populated masters for optical structure replication processes, IR lens batch machining and optics at wafer level.

With DPI®, the outstanding form accuracy, surface finish and geometric freedom that is achievable by ultra-precision diamond turning on a single on-axis lens can be obtained on each lens of each array of a fully populated master.

This technology brings many advantages compared to classical freeform machining techniques like amongst others: lower surface form error, reduced machining times, increased geometrical freedom, true 100% fill factor (with extremely sharp edges between intersecting lenses), lower surface roughness, etc, which makes DPI® a unique solution for your next lens array application.

Offering Specifications

DPI® On-axis Diamond Turning

- Shapes: Aspheres, mild freeforms, each lens can have a different optical definition

- Feature sizes: > 10 µm

- Lens sag: > 10 µm, < 10 mm

- Form irregularity: 100 nm p-v

- Ra roughness: 2 nm

- Edge slopes: < 80°, limited by tool clearance

- 100% fill factor

- Position accuracy: Lens to lens: < 1 µm, MLA to MLA: 1 µm

- Diffractive structures: Yes (axis symmetric)

- Master size: Up to 8”

- Number of lenses: Up to tens of thousands

- Master material: NiP, brass, PMMA, CuBe, Al, …