Freeform masters for replication

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Masters (origination)

-

Market

- Healthcare & Life Sciences

- Lighting

- Security & Branding

- Other

-

Manufacturing Pillar

- Wafer-scale

- Roll-2-Plate

- Roll-2-Roll

-

Technology

- Laser Ablation

Organisation

Offering Description

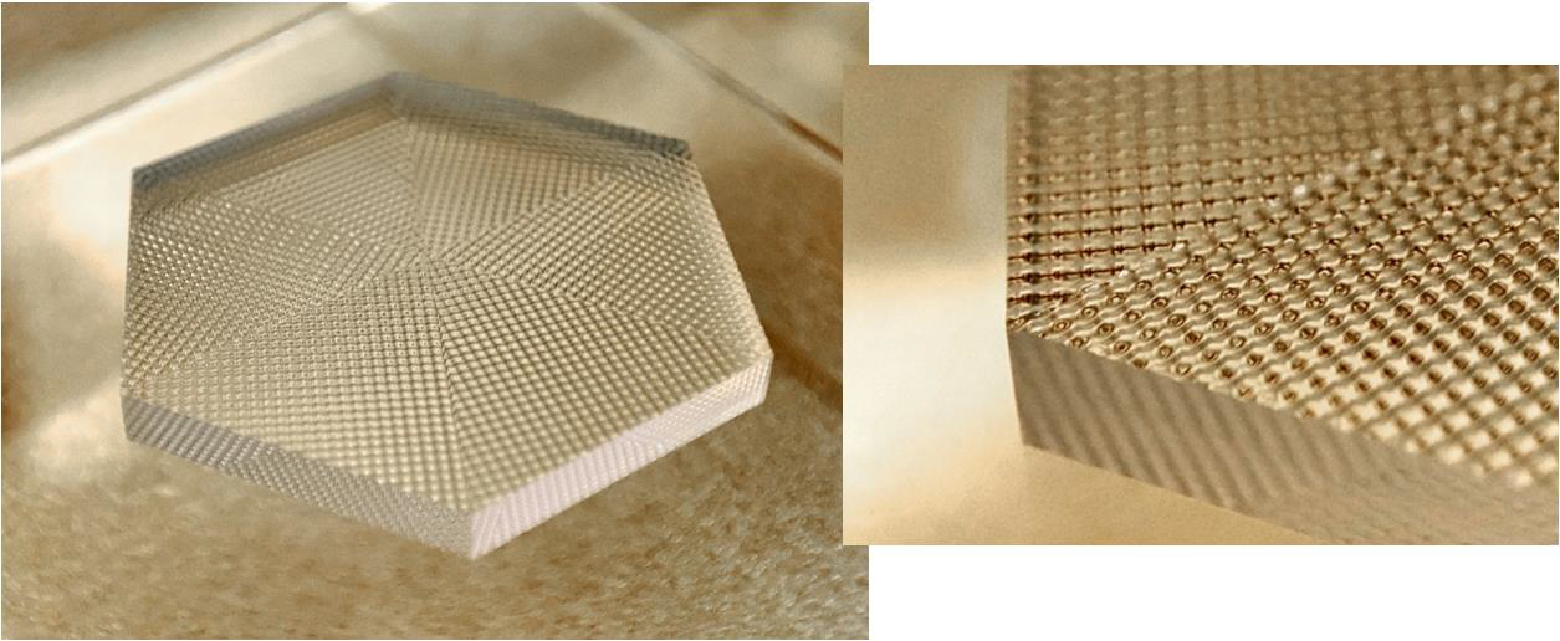

PowerPhotonic fabricates ultra-smooth, high-precision master surfaces in fused silica using its patented direct-write laser process. This method combines high-resolution laser ablation with a proprietary smoothing technique to produce complex freeform or diffractive surfaces without the need for polishing. These masters serve as templates for replication techniques such as UV nanoimprint lithography and roll-to-plate replication.

Our process is ideal for creating tooling-grade optics that maintain form accuracy and optical performance over repeated replications. We also support rapid master development through our LightForge service, enabling fast turnaround times for uncoated prototypes, which can later be transitioned into replication-ready tooling.

Offering Specifications

- Material: Fused silica (quartz) for high durability and thermal stability

- Surface quality: Ultra-smooth finish suitable for optical replication; roughness < 2 nm RMS achievable

- Form accuracy: Sub-micron precision for complex freeform geometries

- Master size: Up to 200 mm × 200 mm