Microlens Array Films

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Volume production

-

Market

- Consumer Products

- Decoration & Luxury

- Imagers & Displays

- Lighting

- Solar, Energy & Daylight

-

Manufacturing Pillar

- Roll-2-Roll

-

Technology

- Grayscale Photolithography - Maskless

- UV-NIL replication

Organisation

Offering Description

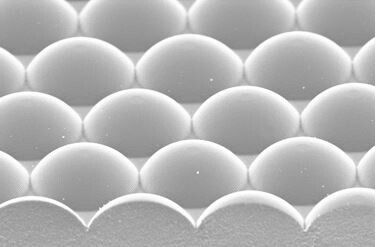

Microlens array films manufactured by UV roll-to-roll imprinting

Top-of-the-line modern lithography machinery (direct write laser, DWL) has enabled significant performance and quality improvement on multilevel or continuous microstructures. One such microstructure is micro lens array, MLA. We can provide customizable, high quality MLAs according to your specfications.

Great tooling is accompanied with highly efficient production technology. UV roll-to-roll imprinting. This enables cost efficient and large volume production of MLA films. UV imprinting has very accurate replication of shapes that can’t be reached with traditional production technologies (IM, hot embossing).

Key benefits of Nanocomp Microlens array films:

- Ultra thin and flexible film components (down to 10µm total thickness)

- Excellent optical performance by precise structures

- Customized arrangements and parameters

Offering Specifications

Specifications

- Shape: spherical, cylindrical, elliptical (convex and concave)

- Arrangement: hexagonal, rectangular (up to 100 % fill factor), custom

- Materials: PET, PMMA, PC

- Max surface area up to 400 X 400 mm, seamless

Applications

- Displays

- Diffusers in BLU

- CCD and CMOS sensors

- Fiber couplers

- 3D imaging and VR

- Security and surveillance