Nanostructuring via plasma processes

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Service

-

Market

- Automotive

- Decoration & Luxury

- Imagers & Displays

- Lighting

- Solar, Energy & Daylight

- Other

-

Manufacturing Pillar

- Wafer-scale

- Roll-2-Plate

-

Technology

- Dry Etching

- Magnetron sputtering

Organisation

Offering Description

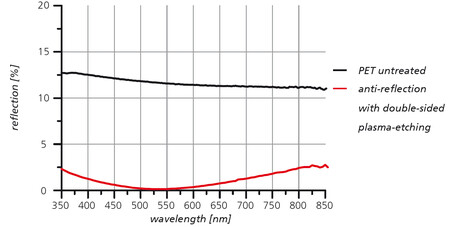

The Fraunhofer FEP, together with the Fraunhofer IOF and industrial partners, has developed a method for making polymer films anti-reflective in an efficient roll-to-roll process. By using plasma-etching in vacuum equipment anti-reflective properties can be applied to polymer films in a more efficient way than with any other currently available process. The process is ideal for very thin polymer films, where the application of a multilayer anti-reflective layer system would adversely affect the film flexibility. Even curved substrates can be uniformly treated using this process.

The Fraunhofer FEP uses dual magnetron systems, which are normally used for coating, as plasma sources for a process which is stable over several hours in order to effectively render polymer films anti-reflective

Offering:

- feasibility studies

- samples for tests and pilot production

- technology and license transfer and modification of existing coating plant

Offering Specifications

- roll-to-roll plasma-etching

- sheet-to-sheet-plasma etching

- treatment speed: 0.5 m/min (per station, up to 6 process stations available)

- plasma sources: Dual magnetron systems

- treatment width: 600 mm

- residual reflectivity: 0.2 percent per anti-reflective side

- low dependence on the angle of observation

- Possible polymer films:

- polyethylene terephthalate (PET)

- triacetate cellulose (TAC)

- ethylene tetrafluoroethylene (ETFE)

- customer-specific substrate

- laquers on flexible substrates