Roll-to-Roll UV Imprint Replication

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Service

-

Market

- AR/VR/MR

- Consumer Products

- Decoration & Luxury

- Imagers & Displays

- Solar, Energy & Daylight

-

Manufacturing Pillar

- Roll-2-Roll

-

Technology

- UV-NIL replication

Organisation

Offering Description

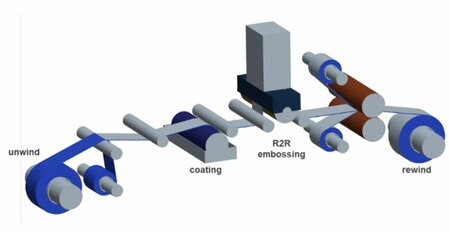

Roll-to-Roll (R2R) UV imprint replication is a high-resolution fabrication method, which is characterized by a high throughput and cost-effectiveness. In the continuous R2R replication process, an UV curable resin is used to replicate the desired structures from a cylindrical tool to a flexible substrate. It has been utilized in the mass-production of optical components, including light guides, diffractive optical elements and microlens arrays. R2R UV imprint replication has demonstrated the replication of high-resolution micro and nano-structures with length scales far below those associated with the traditional manufacturing technologies of plastics (e.g. injection moulding).

Offering Specifications

- High resolution and aspect ratio

- High replication fidelity at high/moderate speeds

- Tailor-able mechanical, chemical and optical properties of the UV resins

- Thin-film compatible

- Room temperature and low-pressure process

- Solvent-free/solvent-based process

- Single-step lamination and coating of samples possible