Step and Repeat NIL

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Service

-

Market

- AR/VR/MR

- Automotive

- Lighting

- Optical instrumentation

- Security & Branding

-

Manufacturing Pillar

- Roll-2-Plate

- Roll-2-Roll

-

Technology

- Other

Organisation

Offering Description

Nanoimprint solutions for the large-scale production of flexible shims and innovative end prototypes

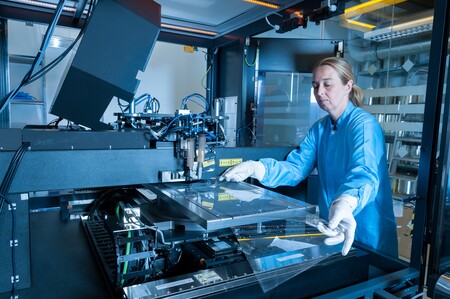

MATERIALS uses a specially modified EVG770 nanoimprint lithography (NIL) stepper for the production of flexible embossing tools for rollerbased NIL in the fields of photonics, functional surfaces and microfluidic systems. Nanoimprint lithography is, compared to other lithographic methods, a cost-effective structuring technology and therefore ideally suited for the use in high volume manufacturing processes. However, the associated time for the production of working stamps (shims) for industrial roll-to-roll imprinting as well as their cost is still significant.

By the development of the step+repeat technology for large-area foil substrates MATERIALS was able to close the gap between small format masters and large-area shims. This enables a remarkably higher process flexibility and further reduction of process costs in the field of nanoimprint technology. The adaptation of the EVG770 system together with EV Group included a sample intake extension for wafer geometries on large-area foil substrates.

Using UV-NIL step+repeat technology, flexible polymer-based shims are created for the use in roll-to-roll imprinting processes. The new approach combines the very high positioning accuracy known from semiconductor technology with foil-based high-throughput methods and offers a cost-effective and industry-compatible alternative to the direct use of conventional time consuming nanostructuring methods.

MATERIALS offers research pilot lines for the development and implementation of new product ideas and manufacturing processes to its customers and partners, from the idea to the prototype. The pilot line for roll-to-roll microand nanostructuring covers simulation, design and material development (coatings, imprint resins) and offers large-scale structuring and structure replication from mastering to rollerbased manufacturing. The EVG770 NIL stepper completes this pilot line with regard to the production of large-area working stamps.

Offering Specifications

- Technology: UV nanoimprinting

- Maximum substrate surface: width: 270 mm; length: 700 mm

- Position accuracy stage: 3 μm