Electroforming Nickel Shims Molds for Replication

-

Offering type ?

PRODUCT:

Component or system, which is commercialized. It is available for ordering multiple pieces and liability is assumed by the provider/seller. Necessary certification of the product was obtained (e.g. CE certification). The product sheet and/or conditions of use are defined.

PROTOTYPE:

Component or system, which has been successfully tested under real or real-like conditions. The prototype is not commercialized as the main purpose is to use it for demonstration and experimentation, including user and market acceptance.

TECHNICAL SERVICE:

Tools and processes and its combination, which are necessary to prepare and test prototypes or products.

- Tooling

-

Market

- AR/VR/MR

- Consumer Products

- Decoration & Luxury

- Healthcare & Life Sciences

- Imagers & Displays

- Lighting

- Optical instrumentation

- Security & Branding

- Solar, Energy & Daylight

-

Manufacturing Pillar

- Roll-2-Plate

- Roll-2-Roll

-

Technology

- Electroforming

Organisation

Offering Description

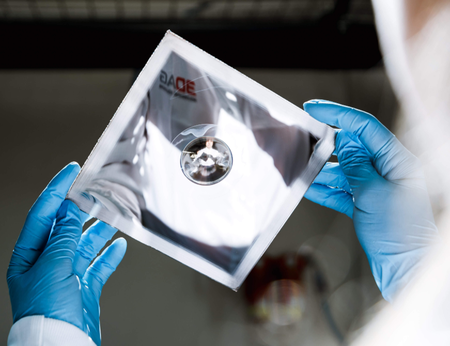

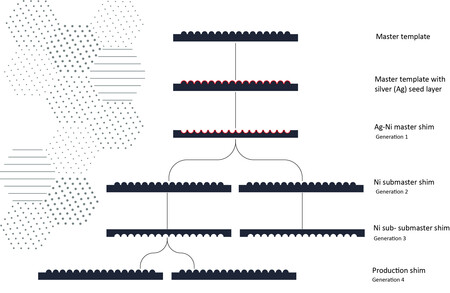

Nickel shims are primarily electroformed to have multiple copies of a structure from a master template and are widely used in prototyping and industrial production. Shims are produced as either thick or fexible molds, and are manufactured by electroforming, a specific electrodeposition process. A common field of use is as inserts for injection molding, or as sleeves for roll-to-roll processes. The micro and nanofabrication of a new original structure can be time-consuming and costly. The goal is to securely transfer structures into nickel shims to guarantee a multitude of usages over time and high-quality molding and replication. The generations and shim family branches are created to sustainably preserve the structure and use it for industrial replication.

Offering Specifications

Base material of your master:

- Polymer,

- Glass

- Silicon wafer,

- Photoresist,

- Metal,

- UV resins

- and others

Dimensions up to nickel shim:

- from mm x mm

- up to 1100 mm x 1700 mm